Drive solutions for logistics in the food supply chain

Big challenges call for great solutions

New logistics concepts and technologies are needed to meet the challenges of our times – from growth and globalization to the boom in e-commerce and the demand for greater environmental responsibility. Our goal is to improve productivity and flexibility with existing capacities.

Digitalization is both a further challenge and a solution. Intelligently networked technologies are performing ever more functions in an increasingly complex economy.

What exactly does that mean for your application? What solutions are available for the various areas of logistics, and how can you use them to meet your current and future challenges? SEW EURODRIVE has the answers.

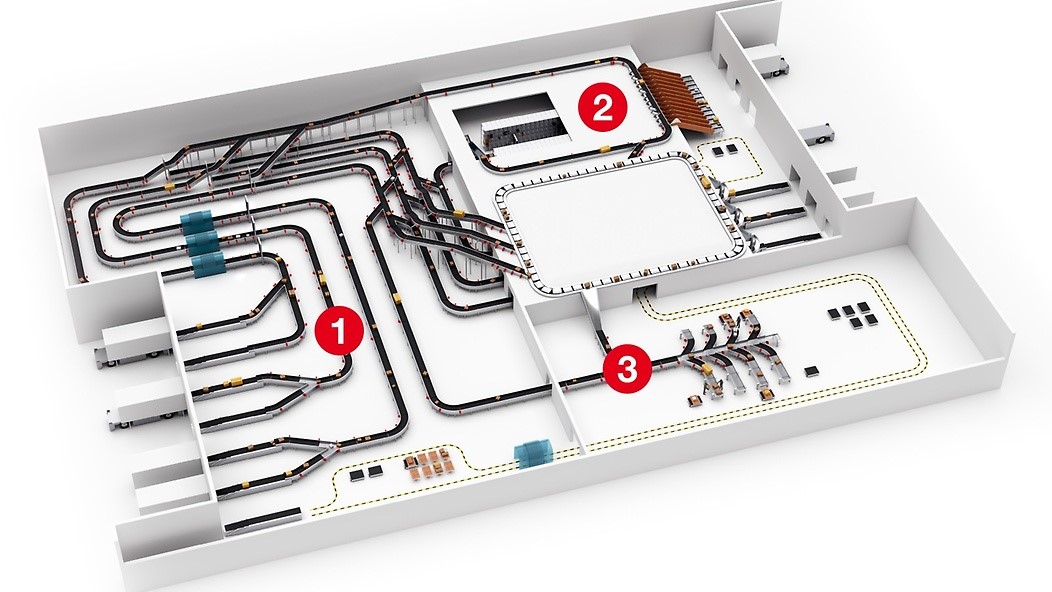

- DISTRIBUTION LOGISTICS

Flows of goods in the food supply chain are becoming increasingly complex. Despite this, deliveries are expected to be fast and cost-effective. Modular systems with energy-efficient components and a high degree of digital networking are the solution. They make logistics processes dynamic, increase system availability and save on costs.

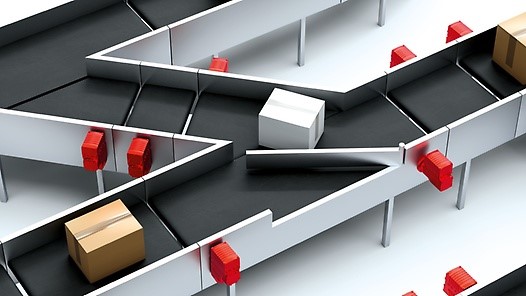

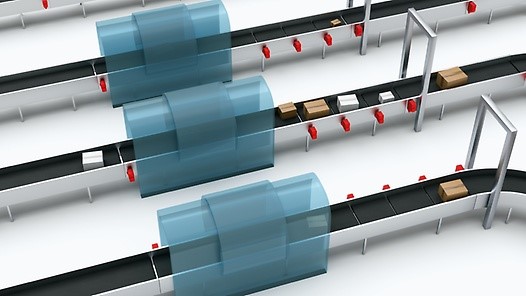

HORIZONTAL DIVERTER:

With the help of the horizontal diverter, the material to be conveyed or the package from the material flow is distributed and steered in different directions.

Application requirements: Exact positioning, limited space in the plant, different sizes and weights depending on the material to be sorted, control of high breakaway torques, reduction of energy consumption.

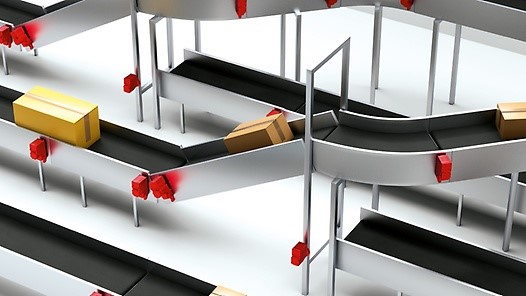

vertical sorter

The vertical distributor distributes and directs goods and packages up and down different conveyor levels in the logistics center.

Application requirements: Exact positioning, different sizes and weights depending on the goods to be sorted, control of high breakaway torques, high mechanical safety (safe package conveying), reduction of energy consumption.

package capture and positioning

In the package entry and package positioning, the most important data of the transported goods are recorded. This includes weight, dimensions of the packages, address data as well as the subsequent positioning.

Application requirements: high connectivity and networking, exact positioning of the goods, fast response time during the process, reduction of energy requirements.

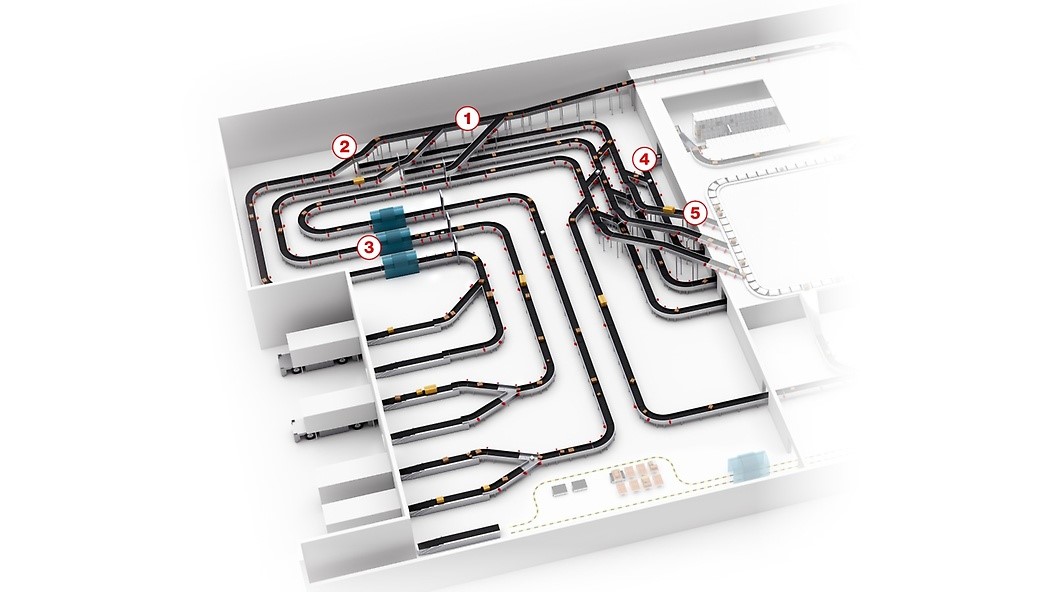

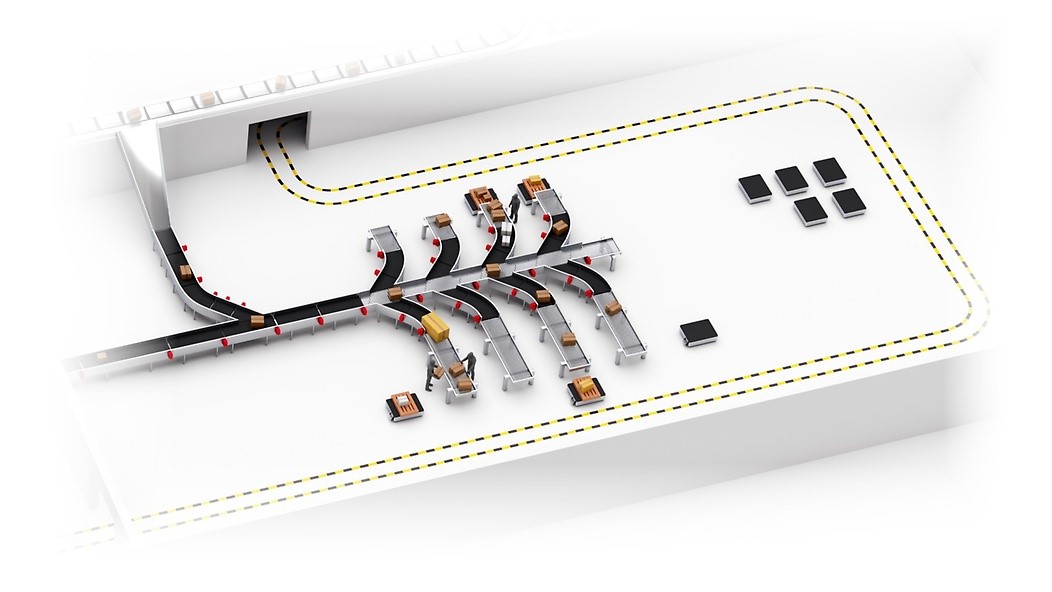

INFEED

During infeed, all transport goods and packages are brought together and directed to the central main conveyor line.

Application requirements: different sizes and weights depending on the goods to be sorted, control of high breakaway torques, dynamic cycle operation, dynamic acceleration for infeed, reduction of energy consumption despite cyclic operation.

OUTFEED

At the end of the logistical conveyor line, the packages are sorted by address and transferred to defined transfer and distribution stations.

Application requirements: energy-efficient continuous operation, long-life drive technology with specific design for continuous operation, early detection of failures.

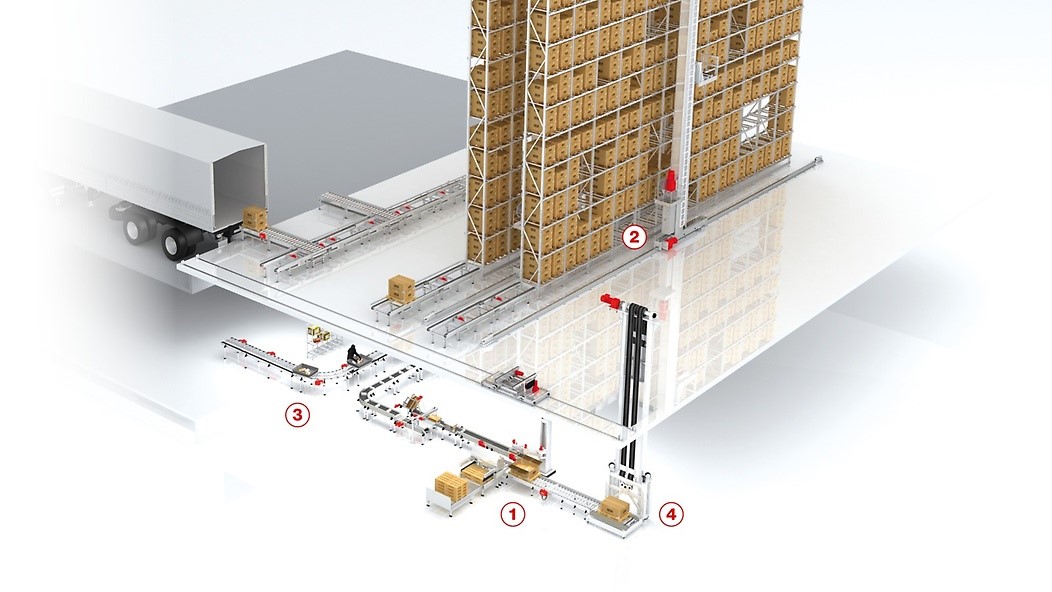

- WAREHOUSE LOGISTICS

CORNER TRANSFER UNIT

In logistics, corner transfer units ensure that the transport of goods is usually diverted at right angles. In this way, corner transfer units contribute to a high material flow performance in warehouse logistics. In addition, corner transfer units are characterized by a compact design.

Application requirements: easy to implement and operate software solutions, high performance with high flexibility, reduction of installation and commissioning costs, condition recording/monitoring.

storage retrieval system

Today, storage and retrieval systems are an integral part of efficient intralogistics. Storage and retrieval systems not only store and retrieve materials and goods automatically, they also support the processes associated with warehousing.

Application requirements: economical storage, low energy consumption, high operational reliability, fast commissioning.

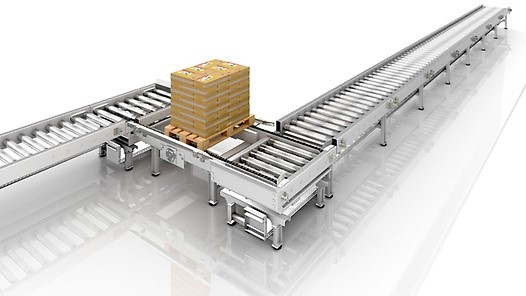

roller, chain, belt conveyors

In order to optimize the increasingly complex flow of materials in industry, stationary conveyors such as roller conveyors, chain conveyors and belt conveyors must also be more reliable, modular, sustainable and even easier to use.

Application requirements: energy saving, safety, networking, low installation and commissioning costs, status detection and monitoring.

lifting station

Lifting stations are equipped with a powerful lifter, which allows space-saving bridging of height differences to other conveying levels in conveying technology.

Application requirements: ensuring the safety of man and machine, energy management, smoothing of the load curve, possibility of local buffering of regenerative energy.

palletizer

New robot technologies are increasingly being used in modern palletizers to augment or replace traditional systems.

Application requirements: high throughput, energy management, simplest solution implementation, low noise level.

- mobile LOGISTICS

α) Transport of containers and pallets

In the field of container and pallet transport, flexible interlinking of plant components and adaptable delivery to production and processing machines are essential. Furthermore, a changing volume of transported goods must be handled reliably.

Application requirements: high degree of automation, sufficient freedom in production planning, fast changeability of equipment and equipment processes, reduction of cycle times for receiving and delivering goods, flexible routing and movement sequences, high personnel safety

β) Rack transport

In rack transport, different loads and transport goods of various dimensions and shapes have to be handled in a mobile and flexible manner.

Application requirements: economic storage, load identification to distinguish different goods, reduction of traffic volume, flexible receiving or transfer points, interaction between manual and automated transport

SEW-EURODRIVE can equip logistics systems with the right machinery for movement in the distribution, storage and goods transport sectors.

ALL ITEMS OF THE GERMAN MANUFACTURER SEW-EURODRIVE ARE REPRESENTED IN GREECE BY THE COMPANY CHR. BOZNOS AND SON S.A.