Electric motors have become a part of everyday life and are necessary in all sectors.

Whether they are motors used to move vehicles, or larger electric motors on conveyors that transport goods, these systems are found in a wide range of industrial applications.

SEW-EURODRIVE electric motors are used, among others:

- in the automotive industry

- in the transport, supply chain and warehousing sector

- in crane technology

Each sector has its own requirements, and therefore also needs the right electric motor.

SEW-EURODRIVE has developed an intelligent machine production system (modular system), where the various parts of the electric motor (individual components) are assembled in countless combinations and adapted to the different needs of customers.

Thanks to this pioneering system, the different electric motors can be individually adapted to the requirements of each application.

TYPES OF ELECTRIC MOTORS AND AREAS OF APPLICATION

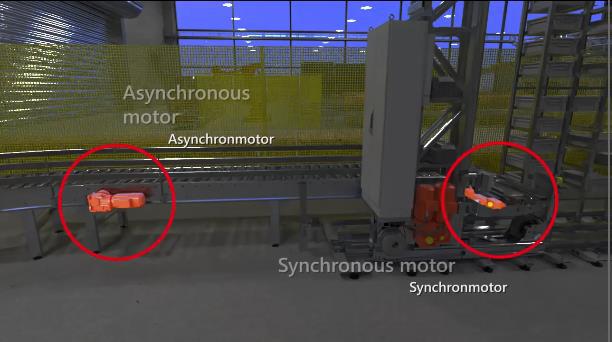

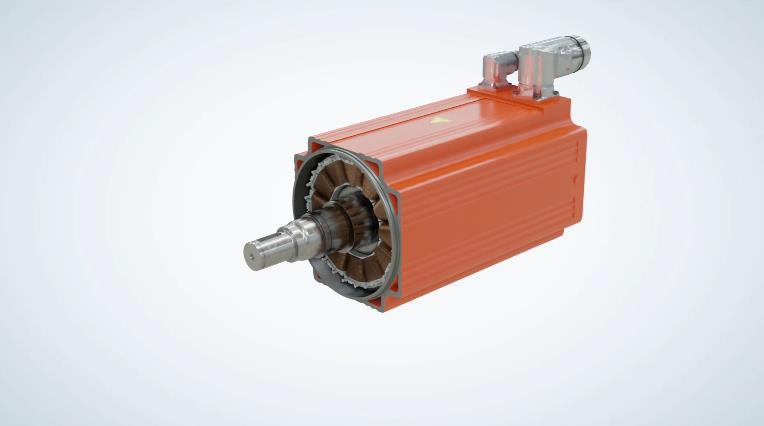

Two of the most commonly used electric motors are the asynchronous motor (AC) and the synchronous motor (SERVO).

But how and where are these motors used?

How are they designed and how do they work?

To show how and where electric motors can be used in practice, let's take a look at an application in more detail.

The application in question is a storage and retrieval system, often encountered in the field of logistics.

It is used to sort goods on pallets or in boxes in a warehouse with shelves at different heights.

Conveyors with rails are used to ensure that there is a flow of goods to or from the storage and retrieval system. Both asynchronous and synchronous electric motors are used in this application.

The storage and retrieval system has modern electric motors for the cargo handling mechanism, which is responsible for accessing goods located in various locations in the storage area.

The electric motors used here must be able to operate precisely and be as light and compact as possible. Modern electric motors are particularly suitable for this, due to their high efficiency.

The conveyor with rails is divided into several sections. An asynchronous electric motor with a suitable gear unit is used for each section. The electric motors used here operate continuously, and therefore must be durable.

Asynchronous electric motors are particularly suitable for this task, since:

- have a simple and robust design

- require minimal maintenance

- they are characterized by their excellent operational safety and reliability

- have a comparatively low price

Similarly, SEW-EURODRIVE’s electric motors are used in the food and beverage industry, brickmaking, shipping, cement industry, chemical, plastic and fertilizer industry, power generation, aluminum and steel, crafts and wherever drive transmission is needed.

AC MOTORS

MAINS INSTALLATION

Για να λειτουργήσει ένας ασύγχρονος ηλεκτροκινητήρας, απαιτείται πρώτα μια πηγή τάσης. Σε απλοποιημένη μορφή, ο ασύγχρονος ηλεκτροκινητήρας συνδέεται απευθείας με την τάση γραμμής. Αυτό θα μπορούσε για παράδειγμα να είναι ένα τριφασικό σύστημα τροφοδοσίας 400 V με συχνότητα 50 Hz. Αυτό επιτρέπει στον ασύγχρονο ηλεκτροκινητήρα να λειτουργεί με σταθερή ταχύτητα. Η ταχύτητα εξαρτάται από τον ίδιο τον ασύγχρονο ηλεκτροκινητήρα και τη συχνότητα της γραμμής.

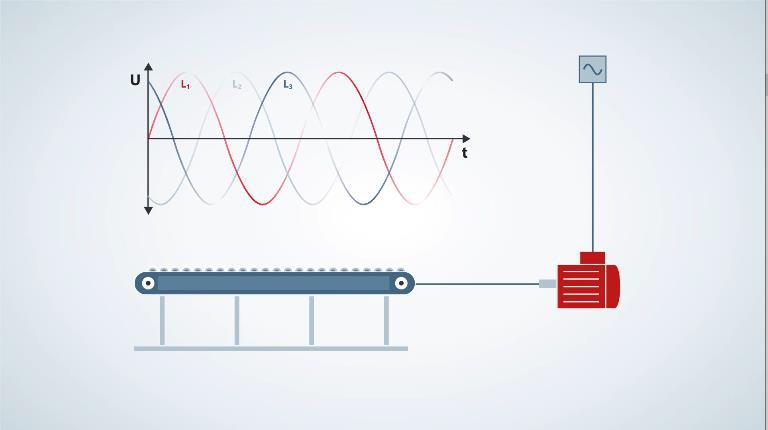

In order for an asynchronous electric motor to operate, a voltage source is first required. In a simplified form, the asynchronous motor is connected directly to the line voltage mains. This could for example be a three-phase 400 V supply system with a frequency of 50 Hz. This allows the asynchronous electric motor to run at a constant speed. The speed depends on the asynchronous motor itself and the frequency of the mains.

INSTALLATION WITH FREQUENCY CONVERTER (INVERTER)

Εάν οι απαιτήσεις για τον ηλεκτροκινητήρα είναι πιο περίπλοκες, μπορεί να χρησιμοποιηθεί και ένας μετατροπέας συχνότητας. Η κύρια δουλειά ενός μετατροπέα συχνότητας είναι να ελέγχει την ταχύτητα του ηλεκτροκινητήρα.

Μπορεί να σας ενδιαφέρει: Μάθετε πώς ο μετατροπέας συχνότητας έχει επιδράσει στον βιομηχανικό αυτοματισμό

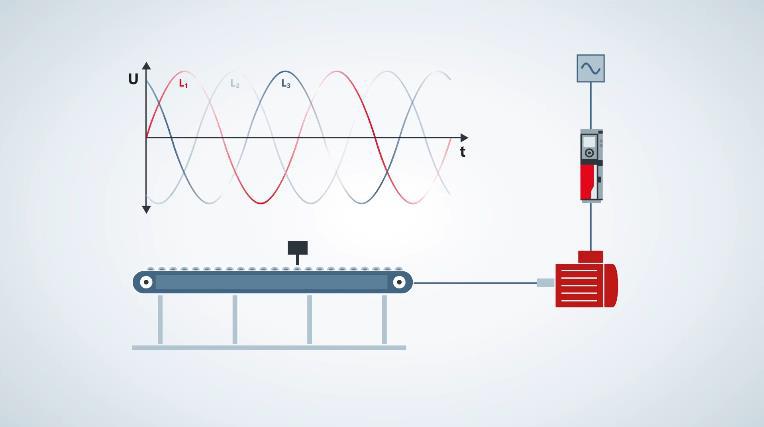

If the requirements for the electric motor are more complex, a frequency inverter can also be used. The main job of a frequency inverter is to control the speed of the electric motor.

You may be interested in: Learn how the frequency inverter has influenced industrial automation

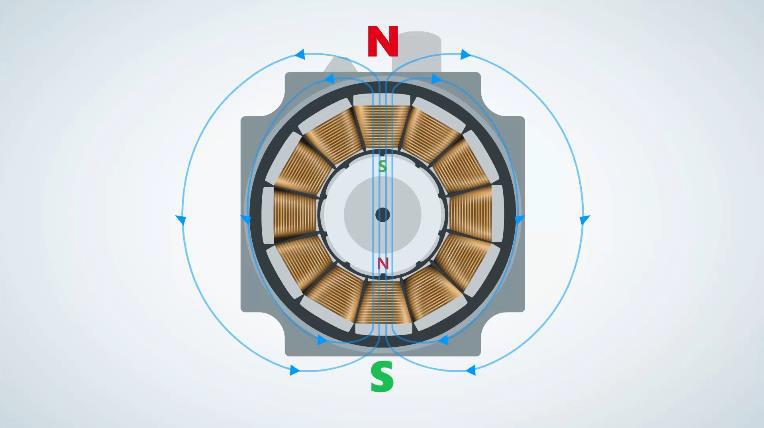

FORMATION OF THE MAGNETIC FIELD OF THE STATOR

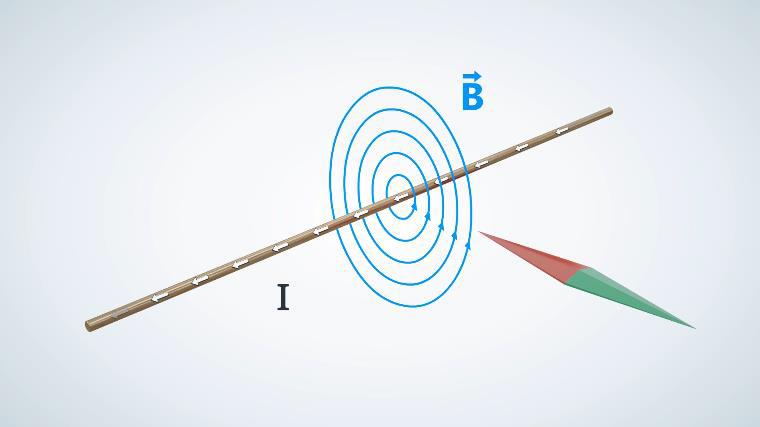

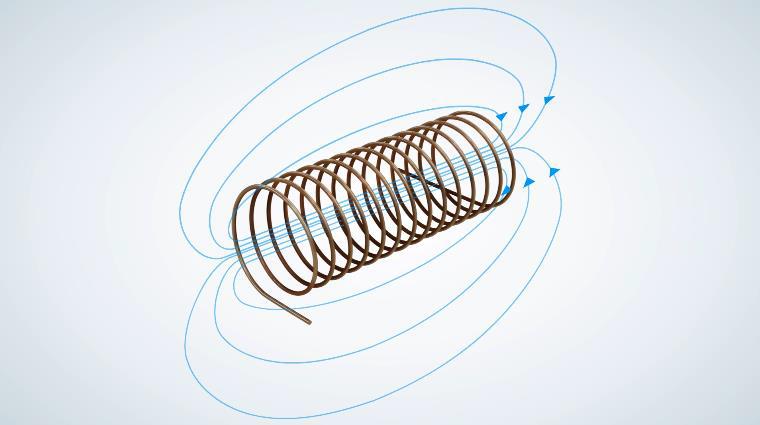

If a current flows through an electrical conductor, it is surrounded by a magnetic field. You can thus create electromagnetism with the help of the electric current.

A greater magnetic effect is obtained with the same amount of current but by rotating the conductor forming a coil. The magnetic field is compressed inside the coil, thus increasing the magnetic effect.

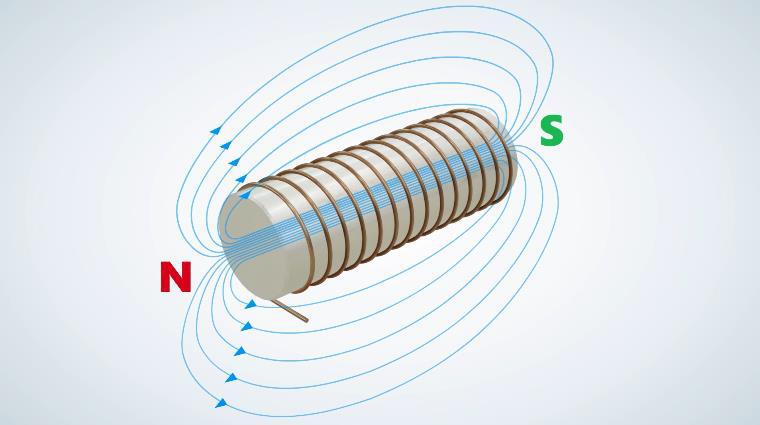

The magnetic north pole is where the field lines exit and the south pole is where they enter. This effect is enhanced by a ferromagnetic core.

ROTARY MOVEMENT OF THE MAGNETIC FIELD OF THE STATOR

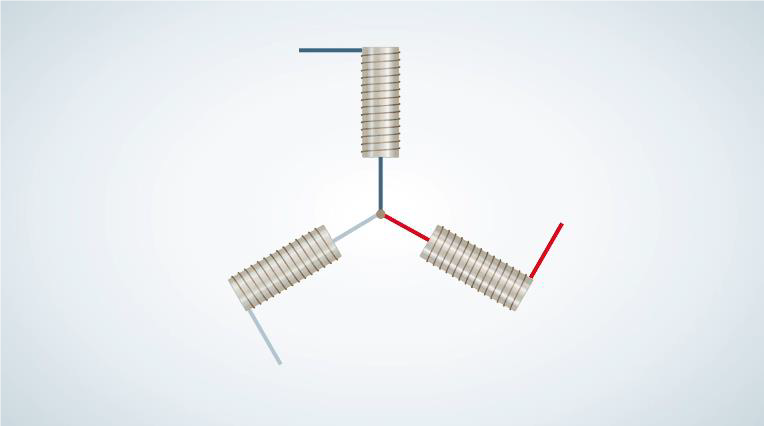

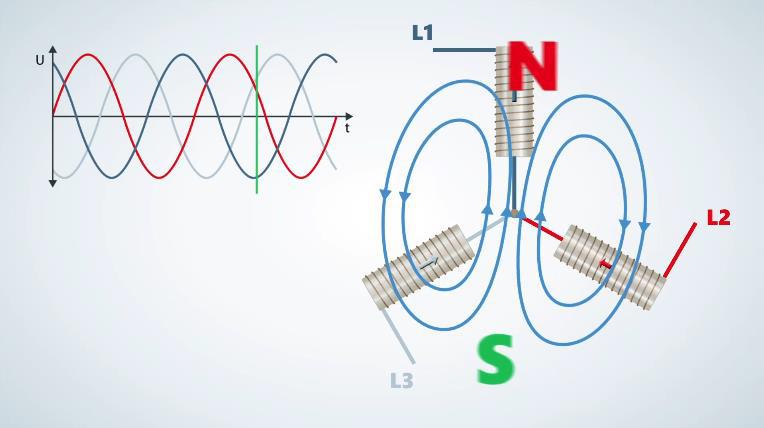

The stator windings are staggered by 120 degrees, which is shown here in simplified form. The electrical connection of the stator windings is known as star connection. These parts of the electric motor, the windings, are connected on one side to one phase of the three-phase current while they are connected to each other on the other side.

There are other important connection types, winding types and winding arrangements, which are used depending on the type of the electric motor and the requirements. The connection is made in the terminal box of the electric motor.

The three phases of the three-phase current create magnetic fields in the three windings of the stator. Considered in more detail, the sinusoidal progression of current strength in the conductor tracks of the stator winding produces a magnetic field of variable strength and direction.

It is this changing magnetic field that causes the rotational motion. The magnetic field of the stator is aligned in synchronization with the three-phase current that generates it and the electric motor rotates.

Read also: How to increase the life of an electric motor

Induction

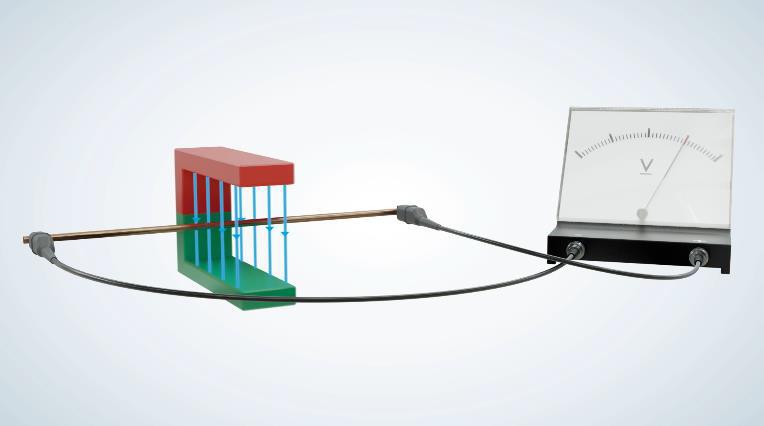

If an electric conductor is in a changing magnetic field, which acts perpendicular to it, then an electric voltage is produced. The largest change in magnetic field occurs when the conductor enters the magnetic field, which is why the deflection of the voltmeter is largest here.

A constant magnetic field does not produce this effect. This principle is known as the law of induction. It is used to generate electricity.

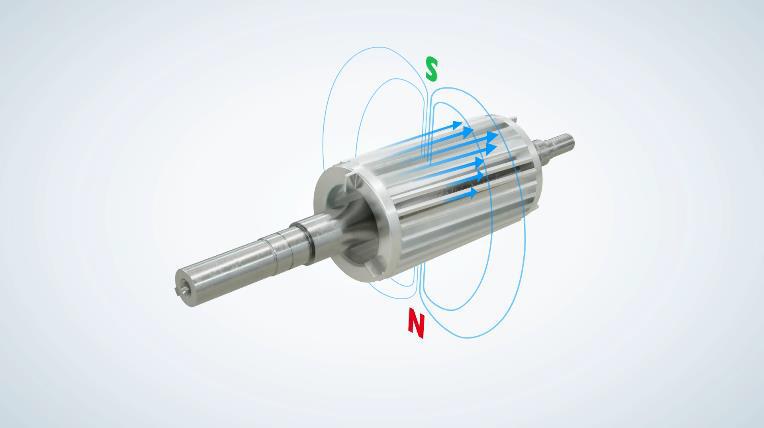

The conducting bars of the rotor in an asynchronous electric motor are arranged perpendicular to the magnetic field of the stator. The rotating magnetic field of the stator thus induces an electric voltage in these conducting bars.

ROTATIONAL MOVEMENT OF THE ROTOR

If a magnetic field acts perpendicular to a current-carrying conductor, it produces a force, which acts on the conductor. This force is known as the Lorentz force and is the cause of motion in asynchronous electric motors. The conductive rod is placed on the periphery of the rotor, one of the basic parts of the electric motor.

The Lorentz force produces a torque along the entire radius of the rotor. According to the law of induction, the induced voltage in the rotor conductor bars is produced only if the stator magnetic field changes with respect to the conductor bars. A change is only possible if the magnetic field of the stator and the rotor do not rotate at the same speed.

Therefore, there must be a speed difference between the magnetic field of the stator and the rotor, which is known as slip. Slip occurs automatically depending on the load on the motor shaft.

The German company SEW-EURODRIVE manufactures electric motors in accordance with EU regulations. with reduced to almost zero slip between rotor-stator to achieve their high efficiency and with low consumption:

DRN Premium Efficiency Series (IE3)

DRU Super Premium Efficiency Series (IE4)

synchronous motors (servo)

Now let's see how servo motors work.

Installation

A voltage source is required to operate a synchronous motor. The synchronous motor cannot be connected directly to the mains voltage.

For this reason, a frequency inverter is used, for example, which could be connected to a three-phase 400 V supply system with a frequency of 50 Hz.

The frequency inverter allows exclusive control of motor speed or torque.

You may be interested in: MOVI-C frequency converter in automation systems

CONNECTION OF ELECTRIC MOTOR COMPONENTS

Let's see how the parts of the electric motor are connected to each other and how they work.

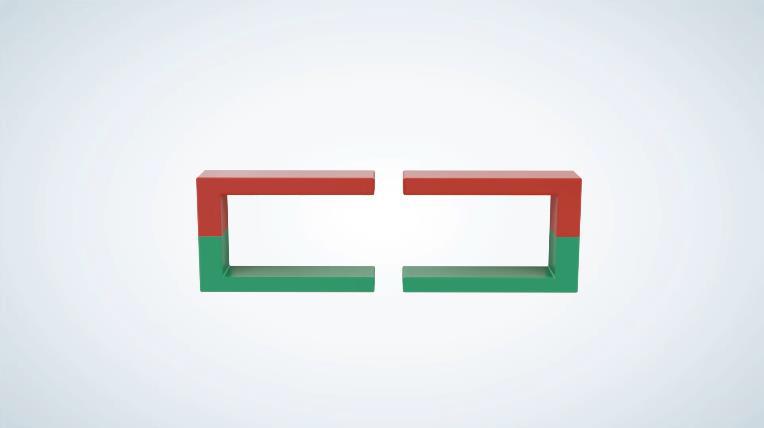

With magnets and magnetic fields, poles of the same polarity repel each other and those of different polarity attract each other.

In the synchronous motor, we have the fixed magnetic field of the rotor and the rotating magnetic field of the stator, which interact with each other.

More specifically, this means that the magnetic field of the rotor adjusts to the rotating field of the stator. The rotor therefore rotates in synchronization with the magnetic field of the stator because it is attracted and repelled by it.

There is no slip with a synchronous motor during normal operation, so there is no difference between the speed of the stator rotating field and the rotor rotating field due to the law of magnetic poles.

However, if a load is applied, the rotor magnetic field lags the stator magnetic field by a certain angle, the so-called rotor displacement angle which increases proportionally to the load.

The maximum torque occurs at a rotor displacement angle of 90°. At this point, the rotor poles are exactly between the two stator poles. This means that the attraction of poles with different polarity and the repulsion of poles with the same polarity contribute to the formation of torque.

The permanent magnet in the center of the rotor is responsible for the synchronous speed and the speed of the stator magnetic field.

The speed of the stator magnetic field can be varied using the frequency Inverter.

For any question about electric motor parts and their operation, please contact us.

The company Chr. Boznos and Sons SA, with its many years of experience in the field of power Transmission, can advise and help you either for the selection of the appropriate electric motor together with the gear unit for your application or for its maintenance and repair.