3 + 1 WAYS TO EXTEND THE LIFETIME OF A GEAR UNIT!

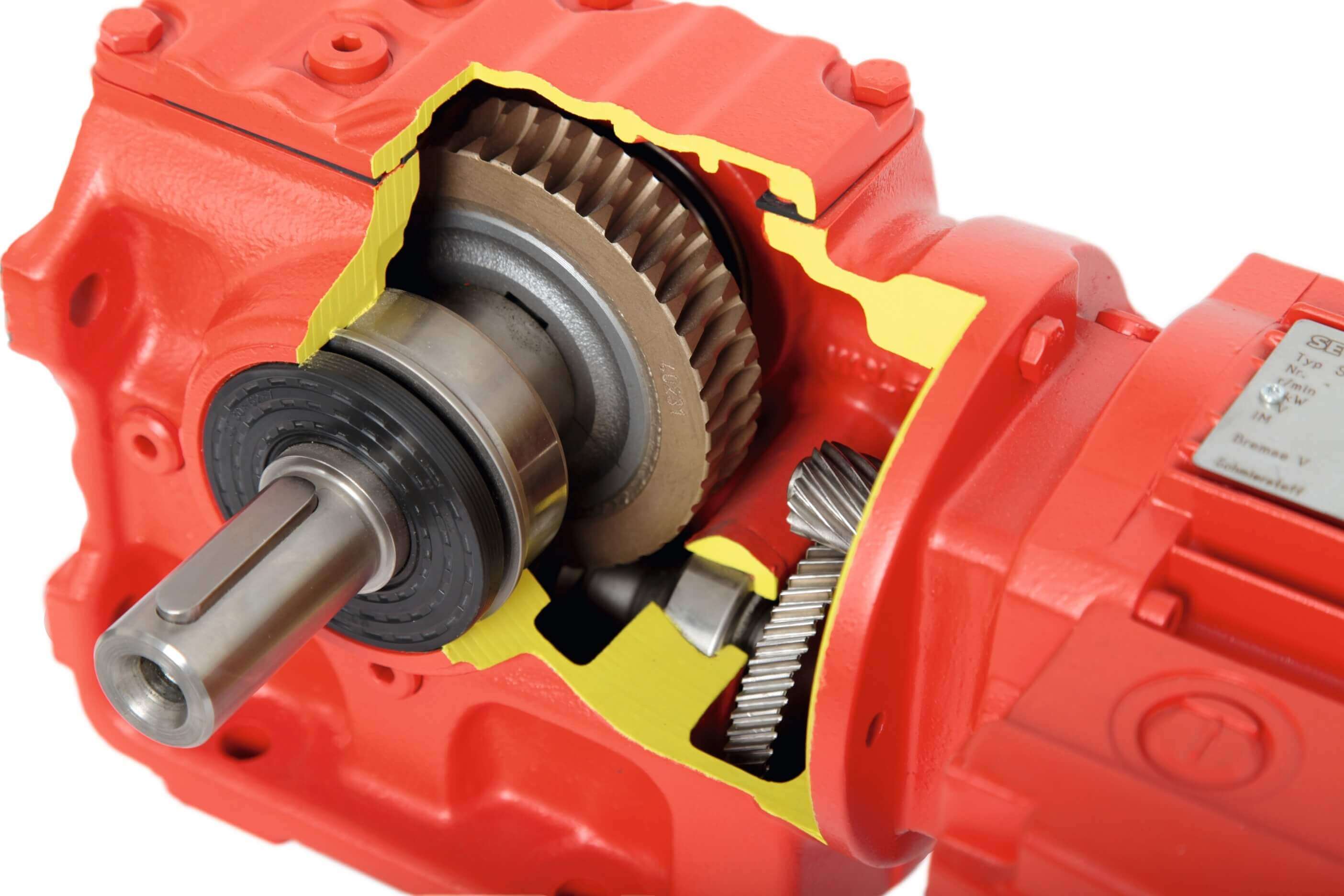

Gearunits are used widely and are part of the main transmission machines we encounter in the industry. The German company SEW-EURODRIVE manufactures every gear unit with reliability and unparalleled quality.

But as with all mechanical systems that have rotating parts, they may wear out during their use. Therefore, if some preventive measures are not taken when needed, they may need to be replaced in the long run.

In order to avoid damages or to minimize them as much as possible, some important inspections must be carried out at regular intervals by the responsible plant engineer, in order to ensure the proper operation of the machinery in the installation.

INVEST IN QUALITY SEW-EURODRIVE LUBRICANTS

The main parts of a gearunit are its gears, which must be properly lubricated with the right amount of lubricant as well as the right type of lubricant depending on its operating conditions.

SEW-EURODRIVE offers a wide range of lubricants which are the most suitable as they are specially designed for the operation of gearunits. SEW-EURODRIVE lubricants minimize gear wear and therefore extend the life of gears, seals and bearings. They also have up to 50% longer life compared to conventional lubricants.

Might interest you: Lubricants SEW-EURODRIVE for gearboxes

CHOOSE THE RIGHT GEAR UNIT FOR YOUR NEEDS

Each gear unit is designed to withstand a maximum load and to operate under specific environmental conditions. We must be very careful in choosing it as in case of frequent overload its mechanical parts can be damaged irreparably. In the company CHR. BOZNOS & SON SA we can help you with the selection and in cooperation with you to find the best possible solution even for the most demanding application.

AVOID OVERHEATING WITH THE APPROPRIATE COOLING SYSTEM

In powertrains and especially in gearunits, the cooling system is very important. In the case of an gearedmotor, the cooling depends on the motor fan which generates a stream of air and cools the surface of the motor and of the gearbox. Depending on the environment, regular cleaning of the fan may be required as improper operation can cause the motor and consequently the gear unit to overheat.

If the gearunit is autonomous (without motor), it does not usually get very hot so, if its surfaces are clean, it cools itself through its shell.

The ventilation valve (breather) of the gearunit, which serves to relieve the pressure created inside it when, during operation, the oil is heated, is included in the same category. When the oil heats up, it must be able to relieve the pressure through the breather valve, otherwise, it may damage the gearbox seals and cause leaks. For this reason the breather plug must always be clean.

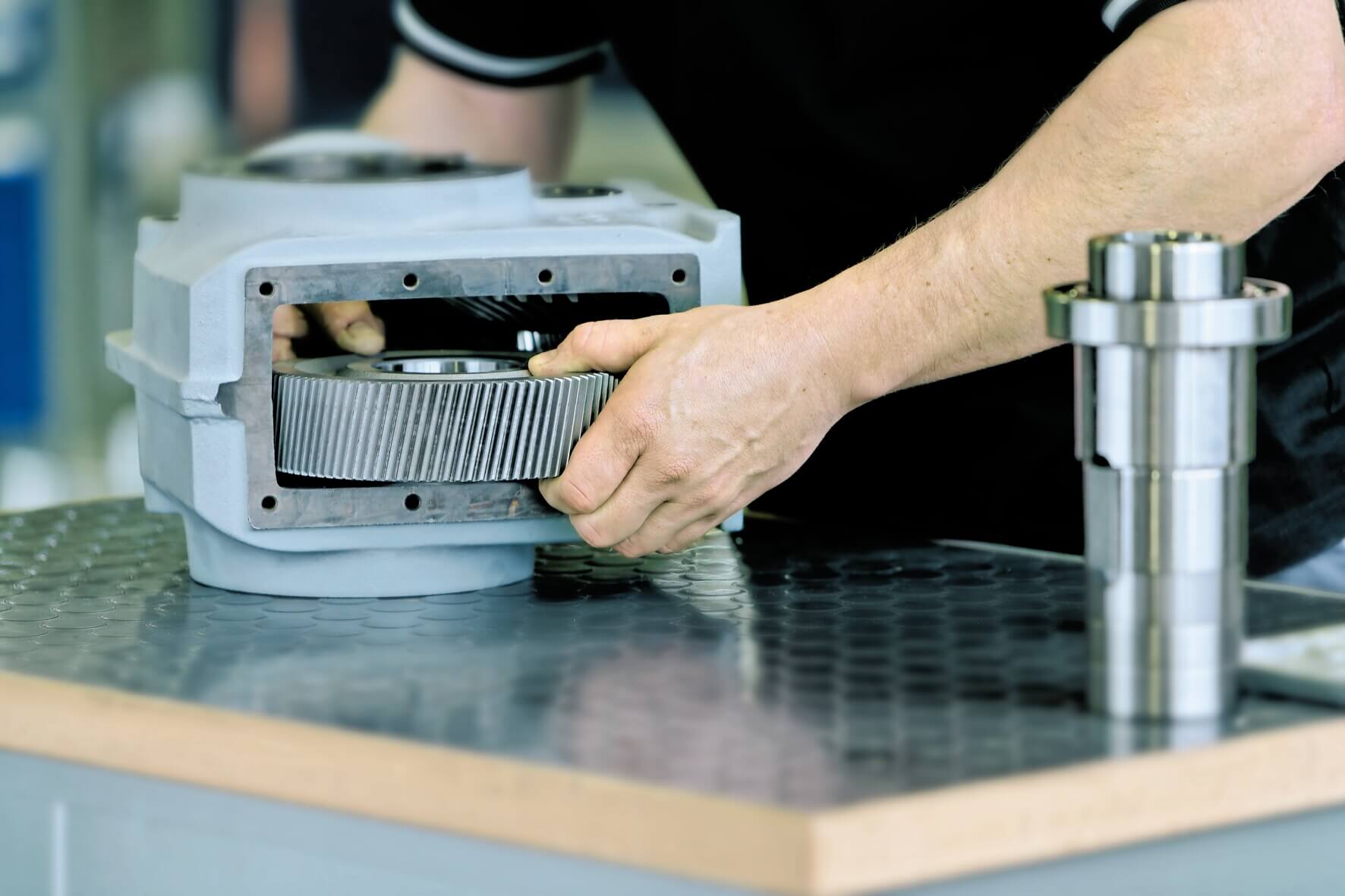

TRUST THE EXPERTS FOR AUTHORIZED MAINTENANCE AND REPAIR

When a gear unit needs repair or maintenance, the best way to ensure that it will remain in excellent condition for many years is to have it done by authorized personnel and with genuine parts.

Repairs cannot usually be performed during the production time and for this reason it is suggested the they are done at regular intervals, outside production time, either in your facilities or in the Service department of our company. This way, no last minute repairs are needed.

In the company CHR. BOZNOS & SON SA we can help you with the repair of your gearunits in case of failure, to provide you with spare parts and lubricants from SEW-EURODRIVE but also guarantee the work done by our technicians so that you can be sure that you will not deal with the same machine soon.

Visit our store today and learn about industrial automation and cargo lifting, and of course ask us all about power transmission systems. We will be happy to assist you!

FIND THE SUITABLE SEW-EURODRIVE GEAR UNIT!