5 + 1 WAYS TO EXTEND THE LIFE OF AN ELECTRIC MOTOR!

Have you ever wondered how to maintain your electric motor so that it works like new?

The maintenance of an electric motor is necessary, as it is the driving component of the whole system and is found in the majority of applications in every kind of industry.

From the initial selection, to maintenance and repair, there is much you can do to make sure your electric motor works properly for many years!

Below we will analyze the main aspects of maintenance to which we should pay attention to in order to ensure the safe operation of electric motors but also to extend their life to the fullest.

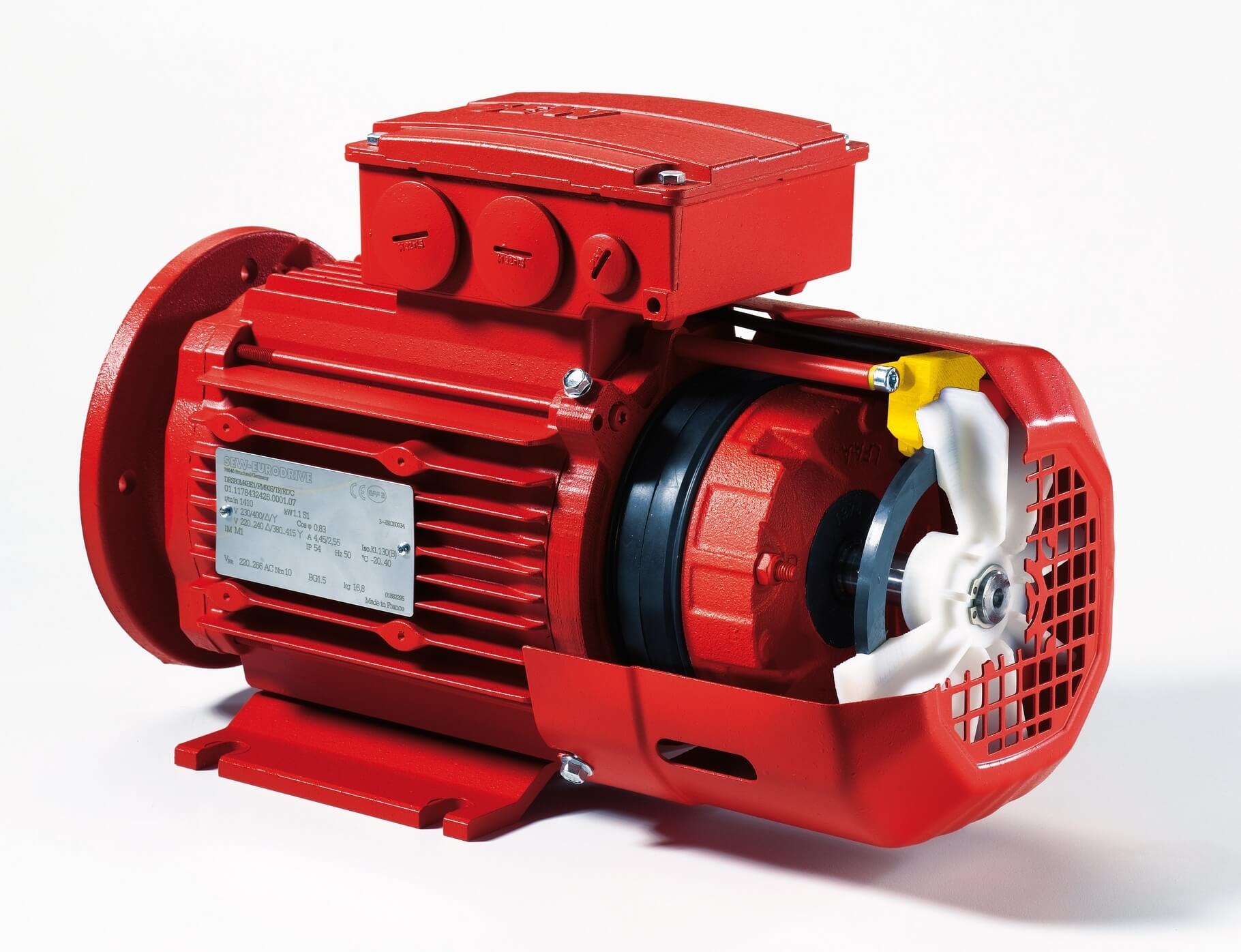

Without a doubt, SEW-EURODRIVE manufactures every single electric motor according to high standards such as reliability and unparalleled quality that ensures its smooth operation. But the user must also pay attention to a few things to avoid problems!

Let's see, then, what the respective engineer can do, in order to maintain the good operation of the unit in the long run.

You may be interested in: What are SERVO electric motors?

LUBRICATION AND INSPECTION OF ELECTRIC MOTOR BEARINGS

The mounting of each machine plays a very important role as the shaft receives all the load. The bearings and the housing in which they are mounted can be damaged, making it impossible to properly support the smooth operation of the unit.

Therefore, the motor bearings must be lubricated and thoroughly inspected at every scheduled maintenance so that if they are worn they do not transfer this wear to the rotor or stator, components that cost more than the bearings.

Do not forget: In case of a wear, the bearings should be replaced with spare parts approved by the manufacturer.

INSPECTION OF THE COOLING SYSTEM AND EXTREME TEMPERATURES BEFORE USING THE ELECTRIC MOTOR

The cooling system of the electric motor is very important as it protects it from overheating, so it should be checked that it is working properly. Regarding the cooling fan, the following aspects must apply:

• It must be in good condition

• It must be able to rotate freely

• The lid should not be blocked with objects or debris

• The air needs to be able to pass freely

Here we should point out that the ambient temperature at which the machine operates affects the electric motor since it is cooled by heat dissipation. So, if the temperature of the environment is too high, the motor will find it difficult to cool down through the heat dissipation, which sooner or later will cause damage or even total breakdown.

For this reason, the extreme operating temperatures should be double checked and in each new application the engineer should provide information about the environmental conditions in which the machine will operate, as the temperature can affect various components, such as bearings, speed control, mechanical brakes etc.

Two very good solutions for the above are to select the electric motor with a thermostat in order to monitor the temperature from the PLC or from a relay on the panel. In case of overheating the relay stops the motor’s operation. Alternatively, a forced cooling fan can be used for more efficient cooling of the electric motor.

INSPECTION OF THE MECHANICAL BRAKE TO AVOID DAMAGE

If the electric motor has a mechanical brake, all its parts should be inspected and if something is damaged it should be replaced because it can adversely affect its operation and it will not brake properly.

BEWARE FOR VOLTAGE FLUCTUATIONS, OVERLOAD OR WRONG CONNECTION

The power supply to the motor is important as it can very easily lead to overload damage, phase loss or incorrect connection. Ideally the electric motor should be operated with a frequency Inverter from manufacturer SEW-EURODRIVE. The Inverter will protect the electric motor from voltage fluctuations and will give options for starting, stopping and operating the unit optimally.

In case of a damage due to power failure, we simply replace the SEW Inverter which only needs a few screws and terminals instead of replacing the electric motor which can often be impossible to reach in an application.

You may be interested in: How does the Inverter Affect the Field of Industrial Automation!

THE CORRECT CHOICE OF ELECTRIC MOTOR BASED ON APPLICATION REQUIREMENTS AND WORKING CONDITIONS

One of the most important things we can do to keep our electric motor running smoothly is to make the right choice of motor to begin with. The right choice depends on the application which determines the size and special characteristics of each electric motor. This means that we must take under consideration the requirements of the whole machine, the operating conditions, special characteristics of the application and in general anything that may affect the operation of the electric motor on the application during the selection process. In the company CHR. BOZNOS & SON SA we can help you with the selection and in cooperation with you to find the best possible solution even for the most demanding application.

PROPER MAINTENANCE AND REPAIR BY SPECIALIZED STAFF

Each machine needs proper maintenance in order to run smoothly over time and proper repair by qualified personnel when required.

At company CHR. BOZNOS & SON SA we perform the maintenance of the electric motors of the company SEW-EURODRIVE Germany, with genuine spare parts, so that your machine is kept in good condition.

Our trained staff with many years of experience acquired from 60 years of cooperation with SEW-EURODRIVE can perform the maintenance and repair of your equipment in our Service Center so that you can be sure of their good operation.

CHR. BOZNOS & SON SA can provide the solution to your every need for industrial automation, drive and load lifting systems with top reliability and excellent results.